Zero Pressure MDR Case Study

Abstract

Within 16 weeks, we were able to design and build a conveyor which had to hold and carry 600 pallets while being efficient, cost effective, and designed for as little field work as possible to reduce labor costs in an epensive labor market region.

Challenges

This project required storage and retrieval of seat pallets which would carry seats for a major electric car manufacturer. The conveyors would inevitably deliver the seats to the mainline then return the empty seat pallets. The system had to installed in an existing assembly plant that provided various unique overhead challenges, as existing columns and trusses that could not be compromised.

The pallets were a standard size (roughly 32” x 60” seat pallets) but we had to have capacity for 600 pallets in this cell. 50 pallets at a time would be introduced to the system from a box truck, and seats were earmarked for specific lines with unique RFID codes for specific vehicles.

The challenge for us was to accommodate a large volume of loaded pallets in a very specific area in the assembly facility. Typically, minimum pressure accumulation conveyors are used in these situations, but the real challenge was the sheer volume and capacity with the accumulated weight. On top of that, the full pallets which introduced the seats to the assembly line also required a return path back to the loading dock, and a last chance induct, repair lane and a secondary storage area was required as well.

Our challenge: design and build a zero pressure accumulation system within a specific real estate while being cost effective. For this customer, field installation and integration was our main concern, and so we had to design our part of the project to avoid unnecessary and costly field labor costs in a geographical area where labor is at a premium. The solution had to be very reliable in order to avoid undo maintenance and repair in a very hard to get to places.

Our Solution

Three tiers, zero pressure Moeller rollers, and poly V ribbed belts

To meet the requirements of this project, we provided a three-tier accumulation and return line above the working area of the assembly plant. The highest point was roughly 24ft above floor with two tiers below. The lowest tier accommodated the return line for empty pallets.

A combination zero pressure Moeller driven 24VDC drive roller zones along with accumulating chain driven live roller conveyor with special metering devices was used to accommodate loading and unloading of pallets from and to loading docks. Air operated pop up chain transfers were used at corners and where lane changes were required. Moeller driven incline belt conveyors in areas where height changes were required to accommodate existing building columns and interferences.

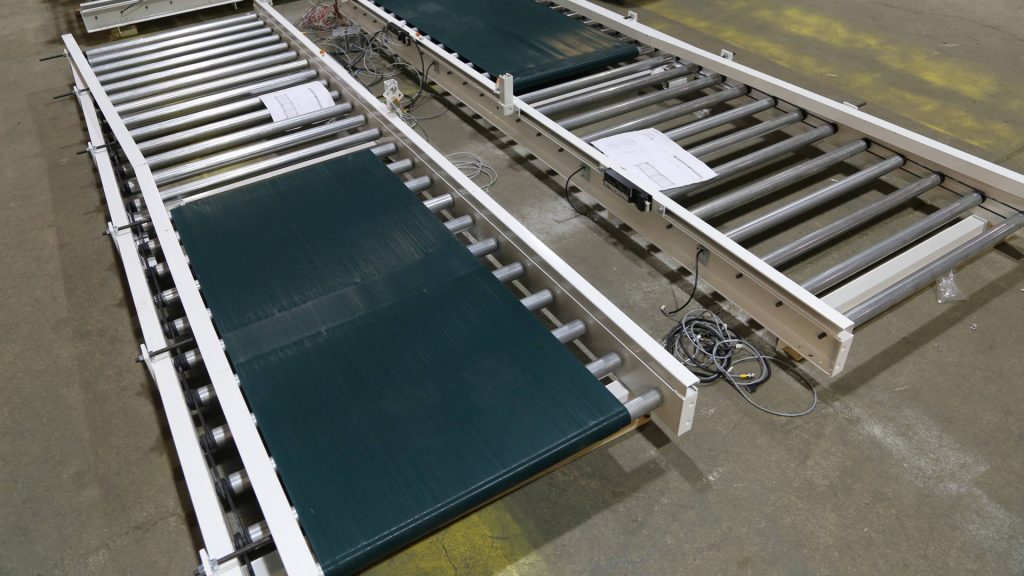

Our system operated with high lifts provided by the systems integrator. We manufactured conveyors mounted on the lifts to interface with our conveyors. Our zero pressure accumulation consisted of MDR (moeller driven roller) conveyors, using 24VDC powered rollers to power each zone using Poly V ribbed belt to belt driven conveyors, as well as a air operated cylinder stop to facilitate transfer of rejected parts onto a chain driven live roller.

A two post top drive lift was designed to accommodate the pallets at three levels. These lifts required a carriage which included a chain driven live roller conveyor along with an integral air operated chain transfer. The challenge was to provide a low profile integral chain transfer to accommodate the low top of roller height required at the down position.

MDR Zone Conveyors

Our standard Lathrup Industries accumulating chain driven live roller multi-tier loader (which has been used in various applications of this nature), proved valuable in interfacing with the new 24VDC MDR zone conveyors.

The Lathrup Loader provided the minimum pressure accumulation necessary for receiving full pallets at the delivery dock. Pallets where metered onto lifts one pallet at a time. Lifts located the pallets at the correct tier where the MDR zero pressure conveyors accumulated the pallets one zone at a time.

MDR zero pressure zone conveyors provided a turnkey accumulation system where the each zone had controls drive card ethernet capable, along with a photo eye per zone along with communication wires mounted prior to shipment from our assembly facility in Novi, MI (on the far west side of Detroit). This solution was designed for the space restrictions, and provided as much of a “turnkey” system as possible to minimize field labor in this specific expensive labor geographic area.

Conclusion

We were able to meet the challenge of providing this complete project from design to manufacture in 16 weeks. This included various 3D modeling of concepts. With our customer and their customer, we met and created various options to come up with the best components for this system.

The final result was a great seat pallet handling system. This systems has since been used as a model for future systems.

We incorporated and modified our standard equipment to accommodate the pallets and work with the provided real estate to provide a solution for a customer that required an accumulation cell in an existing assembly plant.

If you have any questions about this project, or would like to inquire about starting your own project like this one, please feel free to reach out to us anytime at info@lathrupindustries.com.