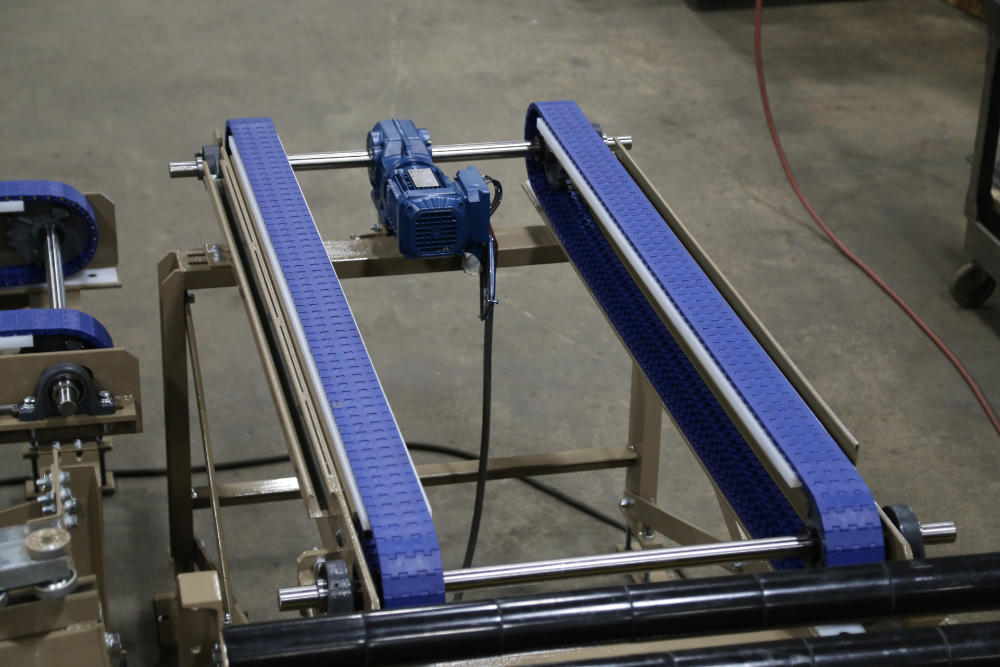

Plastic Belt Conveyor

A plastic belt conveyor is a flexible, versatile transportation conveyor. By utilizing interlocking plastic pieces that allow for bending instead of a traditional belt, the track can truly move in any direction. Plastic belts thrive around curves, inclines, decline, and of course straight sections.

Highlights

Plastic belt conveyors have some key differences over traditional fabric belts, notably that they are positively driven. Fabric belts use friction for drive, which requires the belt follow a specific width to length ratio to ensure proper tracking. Because plastic belts are positively driven and use sprockets to drive the system directly significantly, less tension is needed which allows for seemingly no limit on width and length. Plastic is also flexible, which makes conveying around curves easier and cheaper to design than over traditional belts.

- Positively driven

- Flexible and versatile

- Less belt needs to be replaced for repairs

Use Cases

Plastic belts are versatile and can be found in almost any industry, however, some notable industry use cases are food and beverage, pharmaceuticals, packaging and manufacturing. It is common to use plastic belt conveyors for product justification, sorting, merging, gapping and descrambling by fitting aligning wheels on them.

- Food and beverage

- Pharmaceuticals

- Manufacturing and packaging

Variations

INLINE ROLLER BELTS

PLASTIC BELT ESCAPEMENT

PLASTIC TIRE CONVEYOR

PLASTIC BELT