Rollers

Tapered Rollers

Tapered rollers are not shaped to be perfectly proportioned all the way through the tube. The far side will be larger than close side, and this will help keep the products to move around a curve. Tapered rollers can be designed to be true or untrue. A true roller will keep the product orientation throughout the curve, where as a standard, untrue tapered roller will skew the product slightly. Both are applicable and we will taper the rollers to your needs.

Grooved Rollers

Grooved rollers are rollers with grooves where urethane belts or vbelts run through with power the roller. Most, however, are powered by urethane belts. Generally used in line shaft conveyors, these are most suitable for lighter loads. These can be either slave driven vs other powered rollers, or to be used as pwoer accessories.

Galvanized Rollers

Galvinized rollers are extremely rugged, yet are as corrossion resistant as normal sprocketed rollers. The sprockets, bearings, and axles are all made with mild steel. However, the primary conveying surface is galvanized. These rollers are perfect for conveyors carrying wet products but do not require stainless steel. Galvanized sprocketed rollers are custom made and will meet any specifications.

Sprocketed Rollers

Sprocketed rollers feature multiple sprockets which are welded to the tube, and then driven by a chain. These ase rollers are ideal for pallets, tires, drums or heavy items since the design would transfer some of the torque to the roller. Sprockets can be customized to fit any chain.

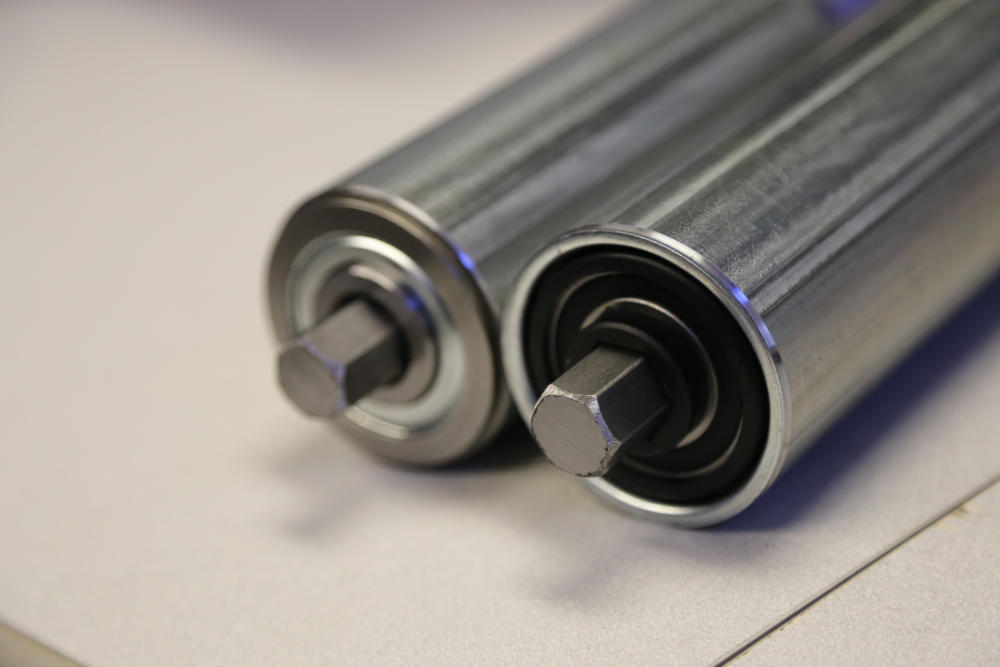

Gravity Rollers

Gravity rollers are the most diverse and practical roller. These rollers can be used for most applications, and unlike other types of rollers like grooved or sprocketed, gravity rollers are not limited to any size. The rollers can be incredibly powerful and our engineers will ensure your roller is perfect. We offer gravity rollers in sizes from 1″ DIA to 6″ DIA. Round axles are available in 1/4 ” to 3 7/16″ DIA. Hex axles are available from 5/12″ hex to 1 1/2″. Many bearing options are available as well as a variety of coatings and sleeves, such as urethane, ultrex, electorplating, and knurling.

Molded Urethane Rollers

Urethane rollers are capable of handling extreme loads and are one of the most reliable rollers we offer. Chemically bonded to an aluminum or steel core, urethane will also help absorb vibration and shock from the assembly line which will reduce damage to the product and the roller. These rollers will last and will keep the downtimes to a minimum. Urethane rollers can be made in many sizes and will be custom made to fit your conveyor.

Technical Information

| Roller Diameter | Axle | Maximum Product Weight |

|---|---|---|

| 1" DIA | 5/16" HEX | 300 lbs. |

| 1-3/8" DIA | 5/16" HEX | 600 lbs. |

| 1.9" DIA | 7/16" HEX | 1,500 lbs. |

| 2- 1/2" DIA | 7/16" HEX | 3,500 lbs. |

| 3-1/2" DIA | 1- 1/16" HEX | 6,000 lbs. |

| 3- 1/2" DIA | 1- 7/16" round | 10,000 lbs. |

| 4" DIA | 1- 7/16" round | 15,000 lbs. |

| 5" DIA | 1- 7/16" round | 25,000 lbs. |